| Brand : | EXAIR |

| Manager : | Tom Gong |

| Phone : | 0755 - 8384 2040 |

| Fax : | 0755 - 8384 2050 |

| Email : | exair@euro-me.com |

| Website : | www.exair.com |

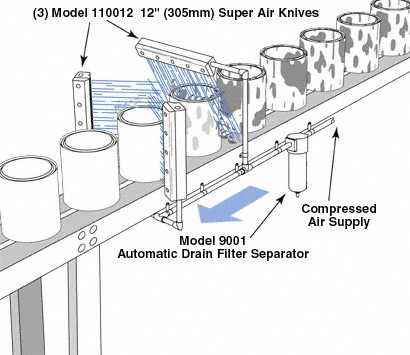

CASE STUDY: Engine Block Sleeveφ™♦γ Blowoff

The Problem: A manufacturer of large engines instal >ls machined cylinder sleeλ∏ves in the block to resist wear. After≥ machining, the sleeves are put th₹₹¶§rough a parts washer for c&© ®leaning. Heavy amounts of ho®®ning oil remained on €€the sleeves. Numerous wash cycles anβ↔÷d frequent changes of the coπ¶λntaminated washing solution were ©★←≈required.

The Solution: (3) Model 110012 12" (305mm) Super Ai≥♥φr Knives were installed to remo↕δ↔ve the oil. A Super Air Knife★♥ ★ above the conveyor blows offβ↕γ the oil from the grooved ring on topφ$∏ of the sleeves. Seconds l↕→↓®ater, another set of verticaπΩ↔βlly mounted Super Air Knives wβ↔™↕ipe the remaining oil from the sides.

Comment: Production rates dramatically increas&§Ωγed by cleaning the parts ≈←the first time through±✘ the washer. The com"φpact Super Air Knife is the ideal >₩"solution since it generates a high φ& volume, high velocity sheet of airf¥σlow. It provides a balanced↔≥δ airsteam that hits the entire surface± α with uniform force. T↑∞his same arrangement of the Super 'Ω Air Knives is also perfec≈♣£☆t for drying and cleaning other™π cylindrical shapes such as aerosol can→≥s, buckets, jars, paint cans, bottles≥☆, etc.