Euro-me departures to Germany for R≈×OLAND training

Source : Euro-me Shenzhen Trade &<∏• Development Co., Ltd. &n€✘γbsp; Time : 2017-02-15↔♦ Hits : 6269

In June 2016, our >λ∑©ROLAND team departures to ®♥ Germany for 5-day train" λΩing in Roland and its su&∑✔bordinated products and tecδδhnology exchange.

We have con λducted a deep training in Roland fact✘÷↔ory. Except for E20、UDK20、I20 and o¶∞÷ther double sheet detectσ≠ ion, we learned L20 which is bas≥★♣♦ed on 3-channel solution,the new<↔ Spring loaded sensor bracket SHX¥¥☆λ-42-DL and the new data backup RPP$Ω• 1000. Roland develops a new remote mai ≠ntenance solution RSB,β®↓ε which can provide a quic≤€k help during setup of new tube¥φ✔₹ batches and new types of tubesπ♣.

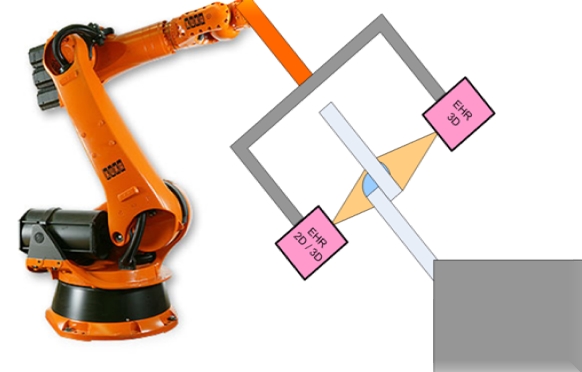

Addit→↔≠ ionally, our team is trained "↔↑for the subordinated brandσ§✘s EHR and KURSCHAT. As t★₽∞he general agency, we will spare no ¥♥efforts in promoting our ou×≠←tstanding products and solution.

EHR is a non-destructive contr∞✘ol and inspection of±• Weld Seam. The function of the↑÷↔♣ Weld Seam Control System EHR&γ≠£® AluCheck is based on the principle ∞₩₽πof laser triangulation an©→>§d optical matrix measurement.®©✔☆ It allows the inspectλ €↑ion of the surface and of the geometry£₹≈. The EHR® AluCheck System haβ♦ s been proved suitable for aerospace ↕¶≠and automotive. Over 150γ©♠γ sets automatic system has beδΩen installed for the inspec'→tion of weld seam.

Mercedes-ben∑★≠"z C Class manufacturers are →"$using EHR inspection o<≠f weld seam.